KONE 2015 | SUSTAINABILITY REPORT

ENVIRONMENT - SOLUTIONS

21

Our long-term environmental objectives are

to further improve the eco-efficiency of our

solutions, and modernize existing elevators,

escalators, and automatic building doors to make

them more energy efficient. In addition, we aim

to further reduce the adverse environmental

impact of our operations, particularly with regard

to our operational carbon footprint as well as

energy, material, and water efficiency.

Energy efficient solutions

for greener buildings

The biggest environmental impact of our

solutions stems from the amount of electricity

elevators and escalators use over their lifetime.

This underlines the importance of focusing on

energy efficiency innovations.

KONE is a pioneer in developing eco-efficient

solutions in the elevator and escalator industry.

The KONE MonoSpace® 500, our current

machine-room-less volume elevator, is up to

90% more energy efficient than KONE’s elevators

from the 1990s. This has been made possible by

the completely renewed low-rise volume KONE

EcoDisc® hoisting machine, a highly efficient

drive, enhanced standby solutions, and LED

lighting. Our revolutionary KONE UltraRope™

high-rise hoisting technology cuts the energy

consumption of a 500-meter elevator ride by

15%.

Elevators and escalators currently in operation

are aging at a rapid pace, especially in Europe.

A TOP LEADER IN

CLIMATE CHANgE

REPORTINg AND

PERFORMANCE

KONE received the

best possible 100 A

(2014: 100 A-) score

in CDP’s climate change program, and

was included in CDP’s Global A List of

113 (5%) leading companies for the

first time, and in the Nordic Carbon

Disclosure Leadership Index for the fifth

year running.

KONE also made it to CDP’s global

Supplier A List including the top 71

(2%) of suppliers that have been

awarded an A grade for their climate

performance.

In this market equipment aged over 20 years is

expected to increase from 2.2 million units to

3.2. million units by 2020, representing 60%

of the equipment base (Source: European Lift

Association ELA). Elevator modernization can

bring vast energy savings. According to the

Energy Efficiency of Elevators and Escalators

(E4) study supported by the European

Commission, energy savings of up to 63% can

be achieved by modernizing elevators installed

in 1985 or earlier with the best available

technology. On the European level this would

amount to 11.6 TWh.

Over the years, KONE has also worked

on further improving the safety, quality,

and reliability of our escalators. We have

set a target of further improving the

energy efficiency of KONE solutions in our

Environmental Excellence program for 2014–

2016 (Read more on page 29).

Eco-efficiency in every phase of a

building’s life cycle

We provide services that help our customers

achieve their eco-efficiency goals in every

phase of their buildings’ life cycles – from

designing and constructing buildings to

maintaining and modernizing them. We pay

careful attention to the way our services are

produced and delivered to ensure that they are

environmentally efficient.

LONg-TERM ENVIRONMENTAL

TARgETS

PRODUCTS AND SERVICES:

Leader in low-carbon People Flow®

solutions for smart eco-cities

OPERATIONS:

Efficient low-carbon operations

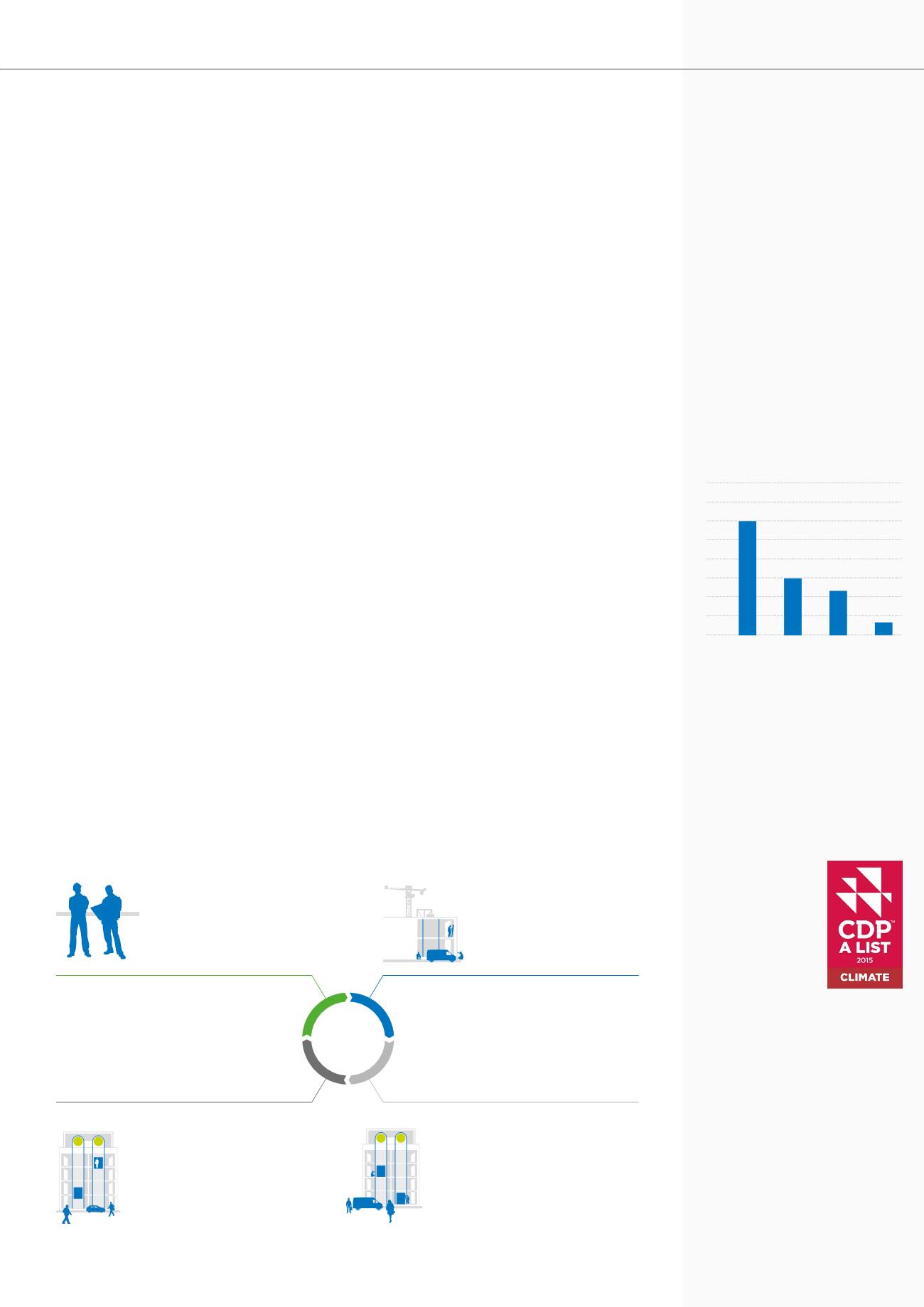

Calculation is based on:

Speed: 1 m/s, load: 630 kg

Since 2008 also: 150,000 starts per year,

travel height 9 m, 4 floors

Due to historical reasons, the data for

starts, travel height and floors is not

available for the 1990s elevators.

ENERgY CONSUMPTION OF KONE

ELEVATORS

Annual energy consumption (kWh/year)

Current

KONE

Mono-

Space

technology

2008

KONE

Mono-

Space

1996

KONE

Mono-

Space

90s

KONE

elevators

8,000

7,000

6,000

5,000

4,000

3,000

2,000

1,000

0

Up to

70%

energy savings

by modernizing an elevato

r

2.9%

relative reduction of

vehicle fleet emissions

1. Supporting green

building design

Calculating our products’

energy use and enabling green

building construction. We publish

the environmental impact of

KONE products and contribute

to developing global energy

management standards.

3. Efficient maintenance processes

Using smart technologies and a green

vehicle fleet to minimize emissions and

maximize efficiency. Remote monitoring

solutions reduce unnecessary technician

callouts. By carrying optimized spare part

stocks in our vehicles we reduce warehouse

visits, further decreasing emissions.

4. Eco-efficiency through

modernization

Applying a range of solutions to

make the biggest difference with

the lowest possible environmental

impact. Our modernization solutions

range from retrofitting LED lights to a

completely new elevator with energy-

regeneration technology.

2. Eco-efficient installation

Considering the environment

when installing new equipment.

Our well planned and efficient

installation processes minimize the

adverse environmental impacts of

installation work, and our systems

ensure we reduce our chemical use

and handle waste efficiently on site.